BUBBLE HELMET

VENTILATOR

VIDEO DEMONSTRATION

PROBLEM

India has an estimated 40,000 working ventilators, a number experts

said will be inadequate in case there is a surge in Covid-19

infections that, in approximately 5% of the cases, sends patients to

intensive care units (ICU) with acute breathing problems.The

coronavirus attacks people's lungs, in some cases compromising their

ability to breathe as they develop pneumonia. Ventilators, which

deliver air to the lungs through a tube placed in the windpipe, are

crucial to keep these patients alive. Mechanical ventilators are

creating more problems than it is solving for ARDS patients.

What are the primary risks of a BVM/Mechanical ventilator?

Being viewed as a viable alternative to available professional care or

delaying seeking professional care. This should be viewed as an

educational resource or a last resort option only unless it’s medical

viability is proven otherwise. Community driven engineering

efforts like this run the risk of making it "too easy to be harmful"

which would be a bad outcome. Using non-invasive interfaces (such as

masks and mouth pieces) can create aerosolized viruses infecting the

medical personnel working in close proximity to the patient. This can

lead to exponential transmission of the virus. Usage should be

restricted to places where aerosolized viruses are already abundant

(lots of unmasked symptomatic individuals), COVID wards, or in

isolation.

SOLUTION

In the event that COVID-19 hospitalizations exhaust

the availability of FDA/ICMR approved ventilators. This

project documents the process of converting the available

compressed air and oxygen tanks at hospitals into a rudimentary

non-invasive pressure support ventilator that could help with

breathing during respiratory distress. It's an evolving project,

but in its current form, it most aligned with the definition of a

non-invasive pressure support BiPAP ventilator.

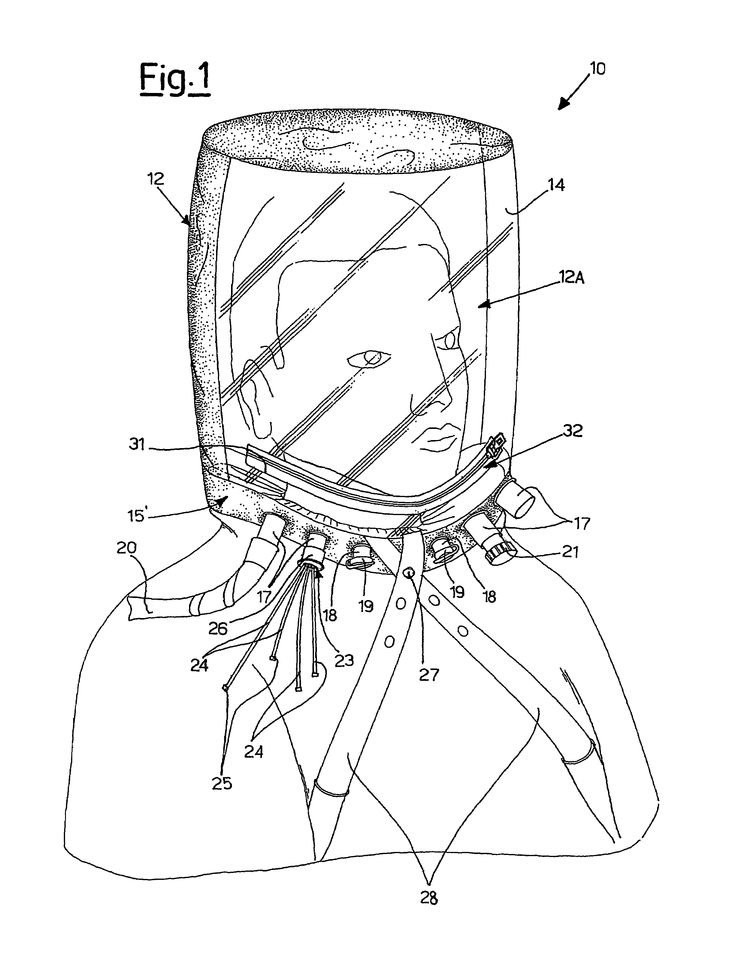

Bubble Helmets are used for patients suffering from

Acute Respiratory Distress Syndrome (ARDS) which

is also caused by COVID-19, the disease caused by the 2019 novel

coronavirus. The helmet surrounds the patient’s entire head to

supply oxygen and is sealed with a soft, airtight collar that

wraps around the neck.

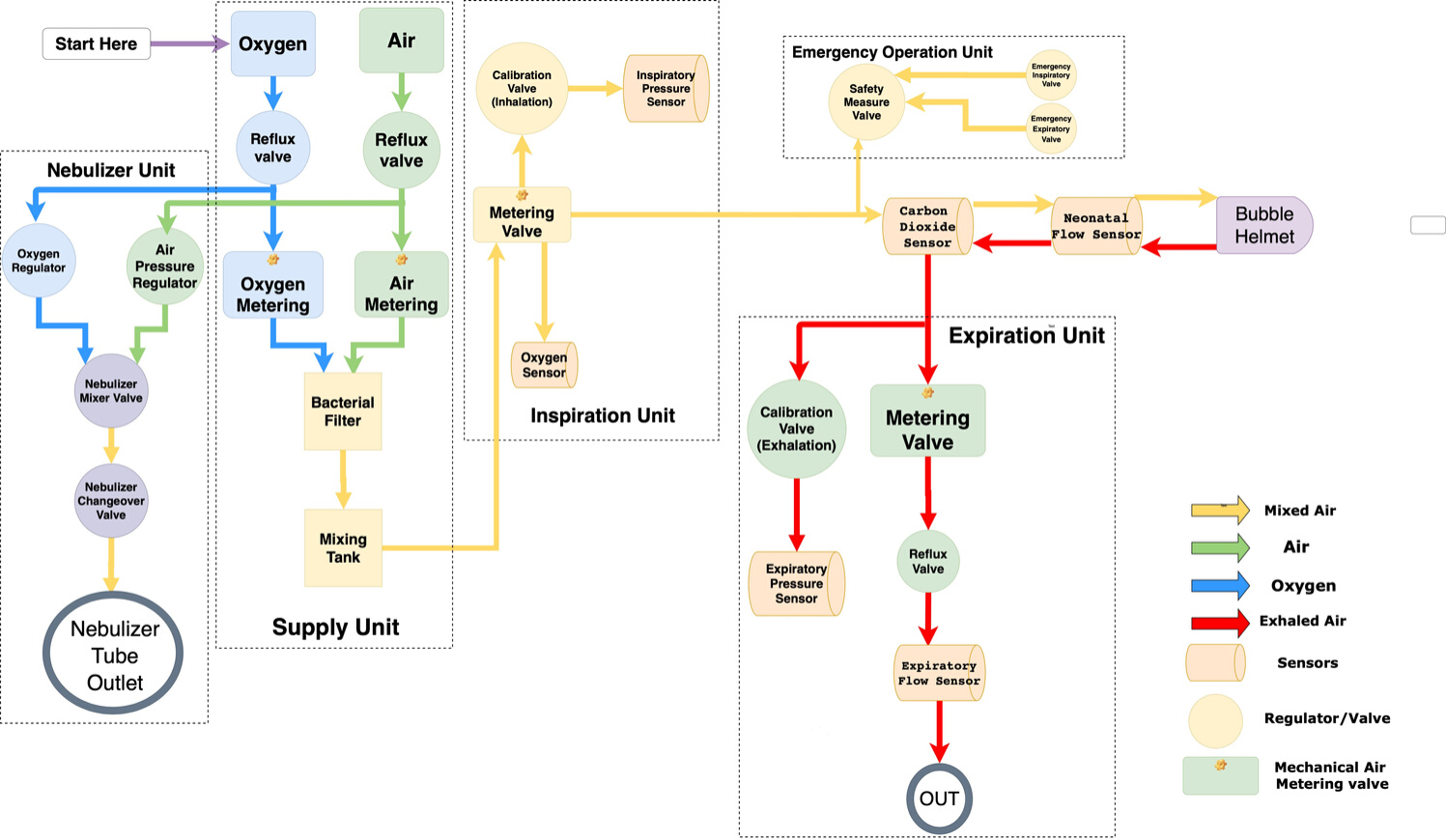

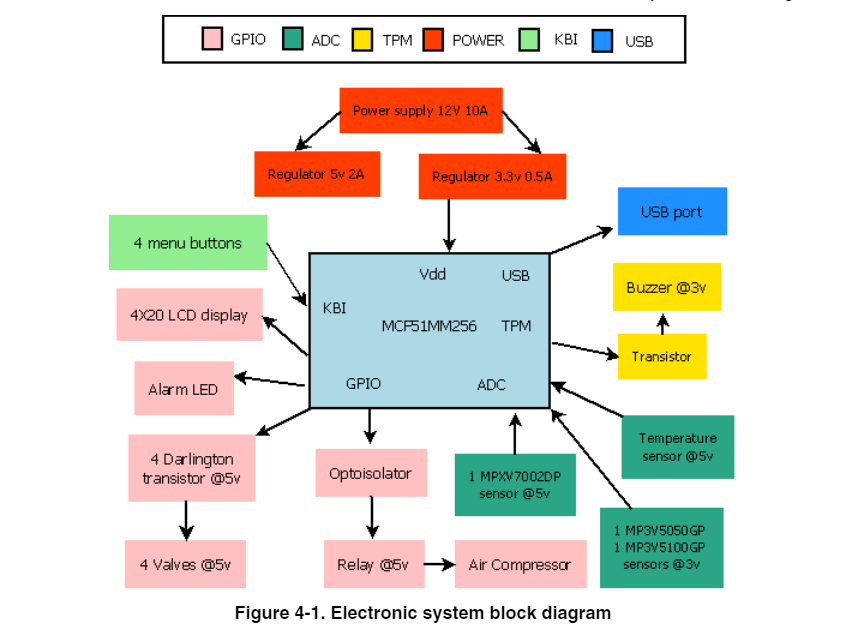

TECH STACK

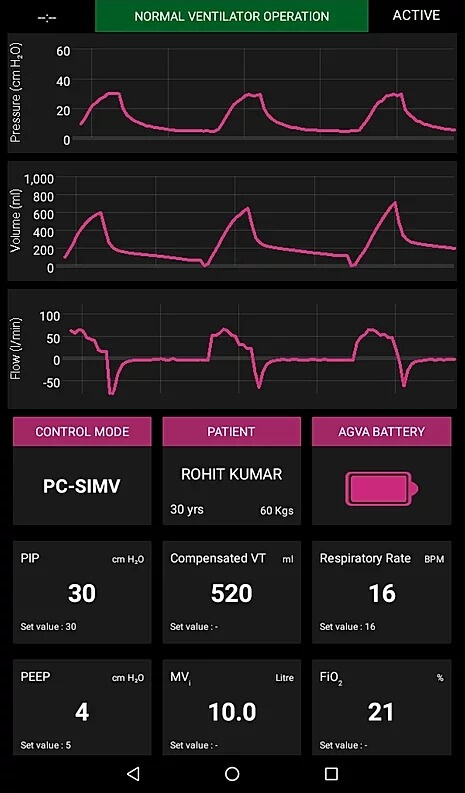

Ventilator

Air gas inlet

O2 gas inlet

Air reflux valve

O2

reflux valve

O2 metering valve

Air metering valve

Mixing

Tank

Mixed gas metering valve

Safety valve

Expiratory

flow sensor

Barometric Pressure sensor

Calibration valve

for inspiratory

pressure sensor

Inspiratory pressure

sensor

Calibration valve for expiratory

pressure

sensor

Expiratory pressure sensor

O2 sensor

Air

pressure regulator

O2 pressure regulator

CO2 sensor

Neonatal

flow Sensor

Nebulizer Mixer Valve

Nebulizer changeover

valve

Nebulizer Outlet

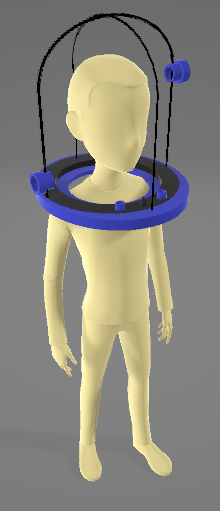

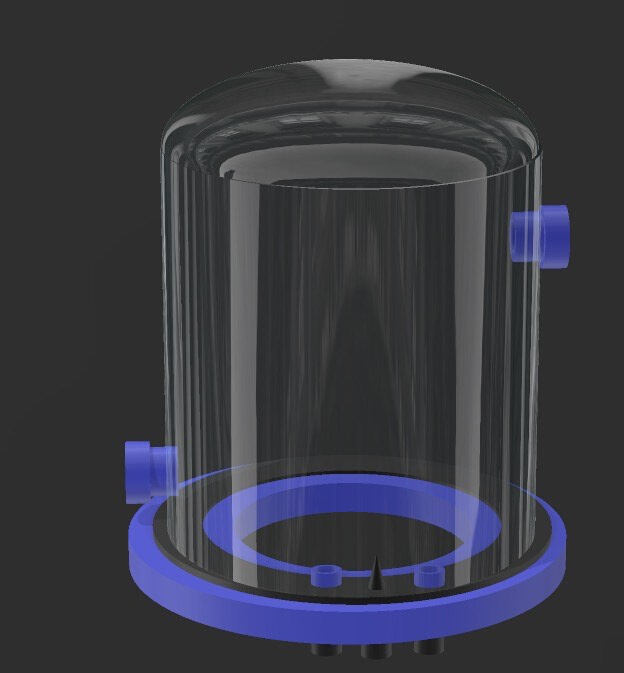

Bubble Helmet

Bubble Helmet components can be made efficiently with 3D printing

and industrial grade tools.

Medical Grade Plastic

Material (Anyone can be used depending on the supply) :

Sustanat

PC MG (Polycarbonate)

FibreTuff PAPC: The 3D printing

material will be used to make Class A, Class B and Class C medical

devices.

Medical grade Non-Latex Synthetic

RubberNeopreneBuna-N

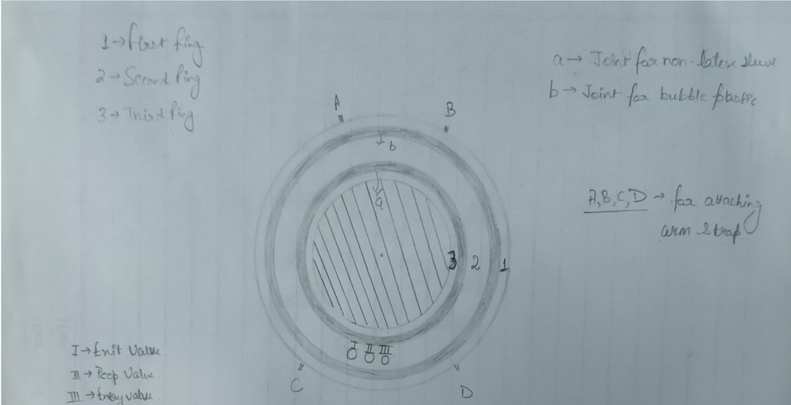

PROTOTYPING

Initial design

Wireframe Desgin

Pneumatic schematic of the Ventilator.

1. Gas-mixture

and gas-metering assembly. Gas from the supply lines enters the

ventilator via the gasinlet connections for oxygen and air . Two

nonreturn valves prevent one gas from returning to the supply line of

the other gas. Mixing takes place in the tank and is controlled by two

valves. Inspiratory flow is controlled by a third valve.

2.

Respiratory unit consists of safety valve and two nonreturn valves .

In normal operation, the safety valve is closed so that inspiratory

flow is supplied to the patient’s lungs. During standby, the safety

valve is open and enables spontaneous inspiration by the emergency

breathing valve. The emergency expiratory valve provides a second

channel for expiration when the expiratory valve is blocked.

3.

Expiratory unit consists of the expiratory valve and a nonreturn

valve. The expiratory valve is a proportional valve and is used to

adjust the pressure in the patient circuit. In conjunction with the

spring-loaded valve of the emergency air outlet, the nonreturn valve

prevents pendulum breathing during spontaneous breathing.

4.

Expiratory flow sensor.

5. Barometric pressure sensor.

Conversion of mass flow to volume, body temperature and pressure

saturated (BTPS) requires knowledge of ambient pressure.

6.

Pressure measurement assembly. Pressure in the patient circuit is

measured with two independent pressure sensors .

7.

Calibration assembly. The pressure sensors are regularly zero

calibrated by connection to ambient pressure via the two calibration

valves.

8. Oxygen sensor.

9. Medication

nebulizer assembly

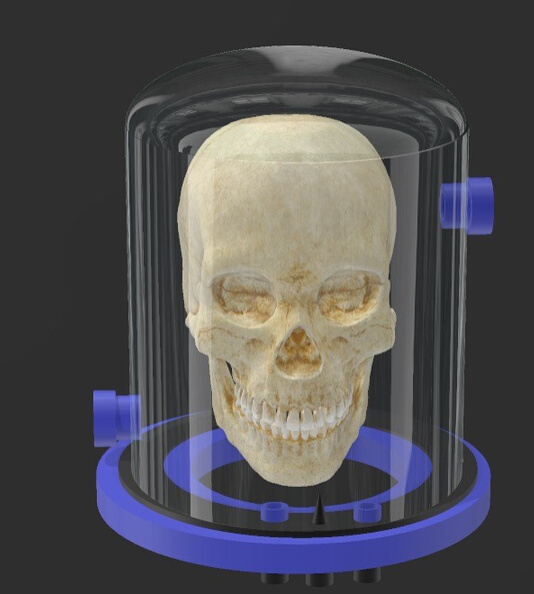

Schematics of the helmet

The primary function of the Bubble Helmet is to provide the

patient with oxygen rich air (as per the patient's requirement) and

also at a higher atmospheric pressure (If required).

The

Helmet is provided with Entry and Exit valves to facilitate the flow

of air inside the Bubble Helmet.

Also two emergency holes

are given in the plastic bubble acting as emergency valves to supply

air to the patient using an ambu bag.

HARDWARE

CAPABILITIES

Ventilator

This design can have a

programmable breathing rate (ex: 10-30

cycles/min.)

It can have a programmed

Positive End-Expiratory Pressure (PEEP).

The Ventilator is physically able to hit

a peak air pressure of up to 45 cm of H2O.

PIP (Positive Inspiratory Pressure) :

This gives the range of pressure we can have in the

hyperbaric chamber (Bubble).

(Range: 12 to 30 cm of H20)

Medication

nebulizer assembly-It is easy and

pleasant to breathe the medicine into your lungs this

way. It is lacking in many other ways, but it is possible that this

limited functionality could be helpful when better care is not

available. It is also a starting point for making progress. Critical

features can be added over time.

Bubble Helmet

The primary function of the Bubble Helmet is to provide the patient

with oxygen rich air (as per the patient's

requirement) and also at a higher atmospheric pressure (If

required).

The Helmet is provided with

Entry and Exit valves

to facilitate the flow of air inside the Bubble Helmet.

Also

two emergency holes

are given in the plastic bubble acting as emergency valves to supply

air to the patient using an ambu bag.

The

patient does not feel claustrophobic, which is a common drawback of

face mask based ventilators.

WHY WE?

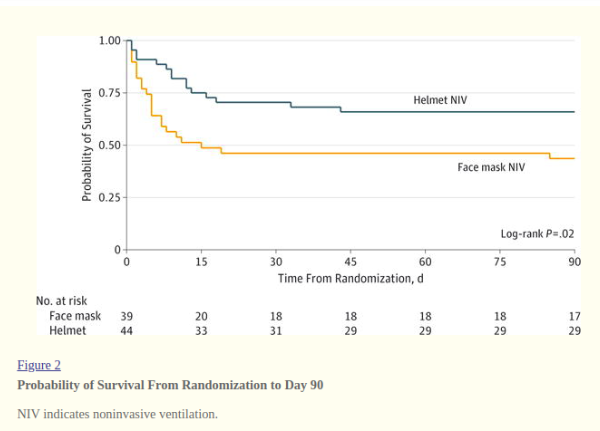

Noninvasive ventilation (NIV) with a face mask is

relatively ineffective at preventing endotracheal intubation in

patients with

acute respiratory distress syndrome (ARDS). Delivery of NIV with a helmet may be a superior strategy for

these patients.Delivering NIV via a helmet interface–a transparent

hood that covers the entire head of the patient with a soft

collar

neck seal, confers several advantages over face mask

including improved tolerability and less air leak due to the

helmet’s lack of contact with the face. Therefore, the helmet’s

design

may allow

increased titration of positive airway pressures

without substantial air leak. This could reduce intubation rates

and extend the benefits of NIV to more patients with ARDS.

The

patient in turn feels less claustrophobic, spends less time at the

ICU and can sooner get rid of the ventilator than the traditional

mask.

Ventilator Powered Bubble Helmet is a much needed rescue from the

traditional masks and ventilators in the time of a crisis.

Its

ability to most of all create a nonclaustrophobic

environment for the patient, who is already under life support is

one of the greatest advancements in medical masks. Along with that

the cost effectiveness and advantage to the patients and doctors

citing its unique shape and design is a winwin deal. COVID-19

crisis is amongstthe worst crisis ever faced by the modern world.

Moreover the consequences of the pandemic will be far more

destructive than the current crisis. It is essential to savethe

resources available for any future need. The product tick these

boxes and since are 3-D printed they are sustainable, and cheap.

This product thereby, stands toe-toe in facing the challenges

posed by this pandemic